一、Overview

Due to the light weight, high specific strength, specific modulus, good ductility, corrosion resistance, thermal conductivity, heat insulation, sound insulation, vibration reduction, high (low) temperature resistance, ablation resistance, electromagnetic wave transmission, wave absorption concealment, designability, flexibility in preparation and easy processability of composite materials, they are ideal materials for manufacturing military weapons such as aircraft, rockets and aerospace vehicles.

Since advanced composite materials were put into aerospace applications, there have been three notable achievements. The first one was that the United States made an eight-seat commercial aircraft - the Lille 2100 - entirely of carbon fiber composite materials and successfully conducted its test flight. The second one is the space shuttle Columbia, which is made of a large amount of advanced composite materials. The main cargo door of this space shuttle is 18.2 meters long and 4.6 meters wide made of carbon fiber/epoxy resin, and various pressure vessels are made of Kevlar fiber/epoxy resin. Resin, metal and ceramic matrix composites were used on this space shuttle representing the achievements of modern technology. The third one is that advanced composite materials were used as the main load-bearing structure to manufacture the Boeing 767 large passenger aircraft that can carry 80 people. This not only reduces the weight but also improves various flight performances of the aircraft. Due to the light weight, high specific strength, specific modulus, good ductility, corrosion resistance, thermal conductivity, heat insulation, sound insulation, vibration reduction, high (low) temperature resistance, ablation resistance, electromagnetic wave transmission, wave absorption concealment, designability, flexibility in preparation and easy processability of composite materials, they are ideal materials for manufacturing military weapons such as aircraft, rockets and aerospace vehicles.

The successful application of composite materials in these several aircraft indicates the excellent performance of composite materials and the maturity of the technology, which is a great impetus for the application of composite materials in important engineering structures.

Figure 1 Bombardier Lille 45XR business aircraft

Figure 2 Space Shuttle Columbia (The picture of the crash site is in the upper right corner)

Figure 3 Boeing 767

二、Aviation field (fixed-wing aircraft, helicopters, special aircraft)

Advanced composite materials are used to process main load-bearing structures and secondary load-bearing structures whose stiffness and strength properties are comparable to or exceed those of aluminum alloys. It is currently widely applied in the manufacturing of aircraft fuselage structures and the overall structure manufacturing of small unmanned aerial vehicles.

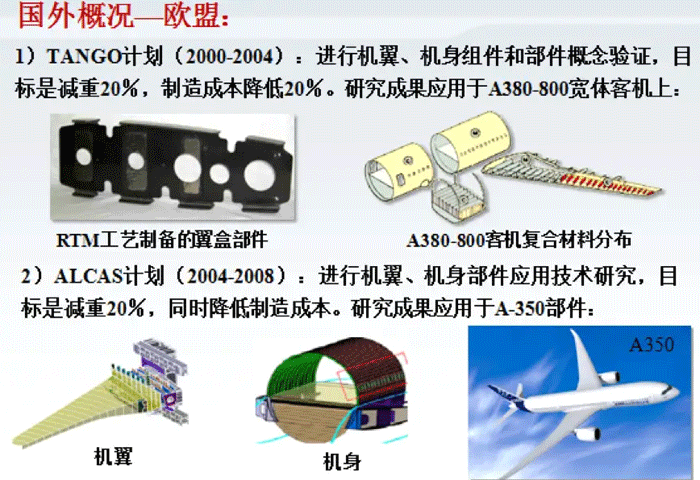

After nearly 40 years of development, composite materials for aircraft have evolved from being initially used in non-load-bearing components to being applied in secondary and primary load-bearing components, achieving a significant reduction in mass by (20-30) %. It has now entered a mature application period. There is no doubt that it can improve the technical and tactical level, safety, durability and maintainability of aircraft. Its design, manufacturing and usage experience has become increasingly rich. So far, the composite materials used in fighter jets account for about 30% of the total materials used, and the new generation of fighter jets will reach 40%. The usage of composite materials in helicopters and small aircraft will reach about (70-80) %, and even all-composite material aircraft will emerge. The fuselage of the Komanchi helicopter is 70% made of composite materials, but it is still planned to reduce the aircraft's mass by another 15% by reducing the mass of the lower front part of the fuselage and expanding the composite materials to the accessories and bearings. To reduce its weight, the Apache will use composite materials instead of metal fuselages.

In the past decade, composite materials have also been widely used on domestic aircraft. For instance, the composite vertical tail wall panel of a certain fighter jet, jointly developed and researched by three domestic research institutions, is 21kg lighter than the original aluminum alloy structure, reducing the weight by 30%. The QY8911/HT3 developed and produced by Beijing Institute of Aeronautical Manufacturing Engineering. Bismaleimide unidirectional carbon fiber prepregs and their composites have been applied to components such as the front body segments, vertical tail stabilizer surfaces, wings, drag plates, and rectifier wall panels of aircraft. The PEEK/AS4C thermoplastic resin unidirectional carbon fiber prepreg and its composite materials developed by Beijing Institute of Aeronautic Materials have excellent fracture toughness, water resistance, anti-aging property, flame retardancy and fatigue resistance. They are suitable for manufacturing the main load-bearing components of aircraft and can work for a long time at 120℃. They have been used in the front skin of the aircraft landing gear cabin guard plate.

According to Boeing's estimation, for every 1kg reduction in the mass of a jetliner, the aircraft can save $2,200 throughout its service life.

2.1 Fixed-wing aircraft

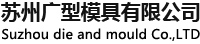

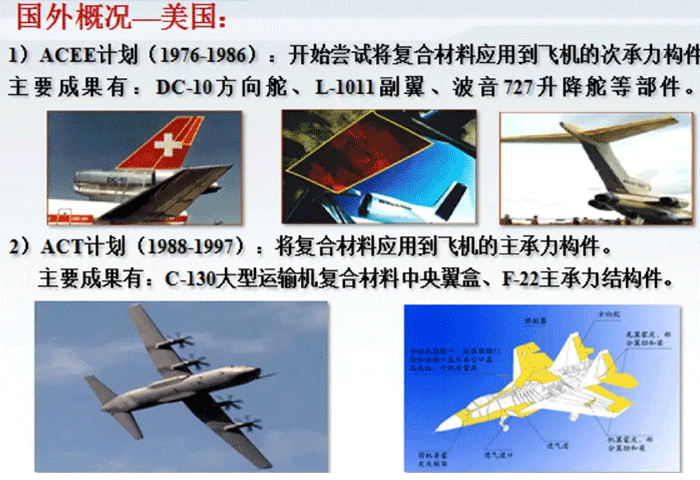

1)Abroad

The usage of composite materials for large aircraft abroad can be demonstrated through the following pictures:

Figure 4-7 Usage of composite materials for large Aircraft abroad

Light sport aircraft (LSA) is a classification name for aircraft proposed by the FAA of the United States in 2004. The maximum takeoff weight of this type of aircraft does not exceed 600 kg (for aircraft taking off and landing on water, the maximum takeoff weight does not exceed 650kg), the maximum level flight speed does not exceed 222 km/h, and the stall speed does not exceed 83 km/h. It is comparable to the stall of traditional general-purpose aircraft, but its fuel consumption is halved and its performance is superior to that of traditional general-purpose aircraft. Single or double seat, fixed landing gear, using propellers with non-variable pitch or pitch adjustable only on the ground, and the power unit is limited to one electric motor or piston engine. Light sport aircraft have few restrictions on maintenance. They can be maintained and inspected by traditional aircraft maintenance technicians, by individuals qualified to repair light sport aircraft, and in some cases, by pilots or owners.

Compared with passenger aircraft and military aircraft, light sport aircraft are smaller in size, simpler in structure, operate in a milder environment, and have more lenient airworthiness standards. Therefore, the application of composite materials in light sport aircraft is subject to fewer restrictions, and the manufacturing cost is lower. Light sport aircraft generally use more than 70% composite materials and are classified as all-composite aircraft. Composite materials have the advantages of light weight, high strength, high modulus, integrated structure and function, integrated design and manufacturing, and easy production of large-sized products. Components made of composite materials can be lighter than those made of metal materials while meeting the same strength requirements.

The Lear Fan2100 aircraft developed by the United States is the world's first all-composite aircraft mainly based on advanced composite materials, mainly CFRP and KFRP, with a structural weight reduction of up to 40%. The light helicopter EC120, jointly developed by China, France and Singapore, uses composite materials in many structures such as the fuselage, vertical tail, tail beam and horizontal stabilizer, in addition to the rotor blades. The JetCruzer 500 six-seat business jet developed by AASI Corporation of the United States has an entire fuselage made of carbon/epoxy composite materials.

Figure 8 Lear Fan2100 aircraft

The market for light sport aircraft is huge, and there are many related manufacturers and models. Currently, this field is mainly concentrated in some developed countries in Europe and America. Well-known manufacturing companies include Cessna Aircraft Company of the United States, Ciri Design Company (which has been acquired by AVIC General Aviation), Diamond Aircraft Company of Austria, and German Flight Design Company, etc. Among them, Flight Design GmbH of Germany is a professional manufacturer specializing in the design and production of light sport aircraft worldwide. The CT series of light sport aircraft it has developed basically all adopt carbon fiber composite material fuselages. Most of the Remos aircraft produced by the German Remos aircraft company are made of carbon fiber composite materials. The wings are entirely made of carbon fiber, which are light in weight and have smooth lines. This model might be the most brand-new light sport aircraft model in terms of manufacturing process so far. The main components of the Austrian Diamond Aircraft Company's DA42 "Twin Stars" aircraft, such as the wings, are all made of composite material structures.

Figure 9 Diagram of the Cessna aircraft

Figure10 Map of Xiri aircraft

Figure 11 shows the da42 "Twin Stars" light aircraft of Austrian Diamond Aircraft Company

Figure 12 German Remos aircraft

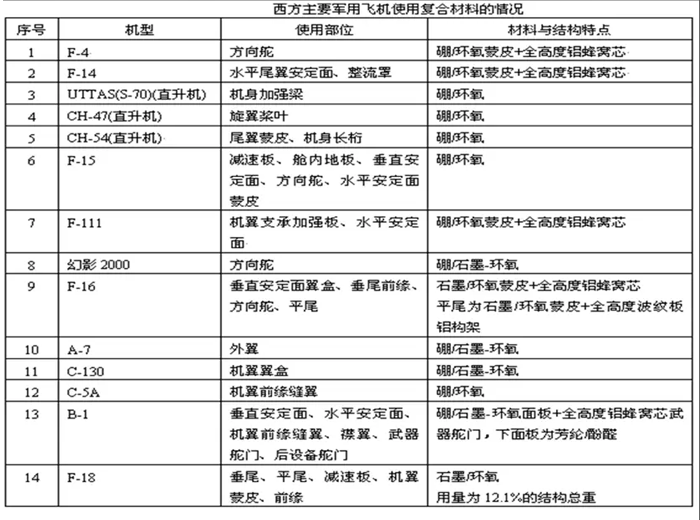

The usage of composite materials for foreign military aircraft is shown in the following figure:

Figure 13 shows the usage of composite materials in foreign military aircraft

2)Domestic

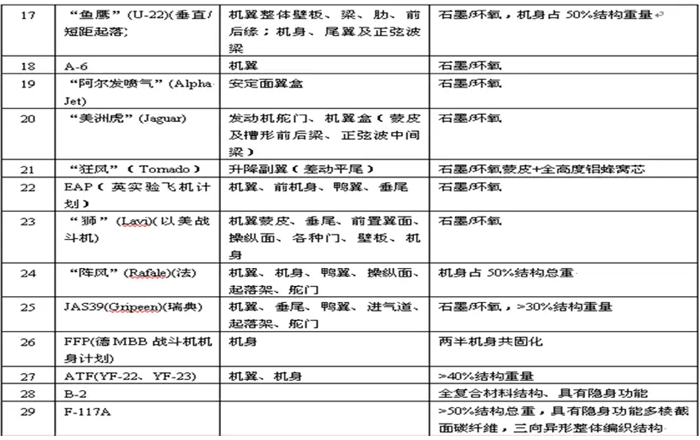

The Y-10 (Y-10) is a four-engine jet transport aircraft developed by Shanghai Aircraft Manufacturing Factory. It was the first large jetliner independently developed and manufactured by China. Based on the industrial foundation and conditions at that time, the Y-10 basically did not use composite material parts.

Figure 14 Y-10 (Y-10)

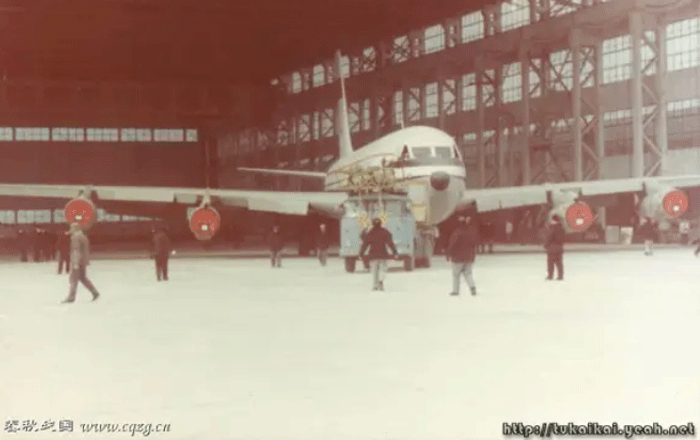

The ARJ21 Xiangfeng, a twin-engine regional airliner developed by Commercial Aircraft Corporation of China, LTD., uses domestically produced carbon fiber for weight reduction in its wingtips and secondary structural components.

Figure 15 ARJ21 Xiangfeng passenger aircraft

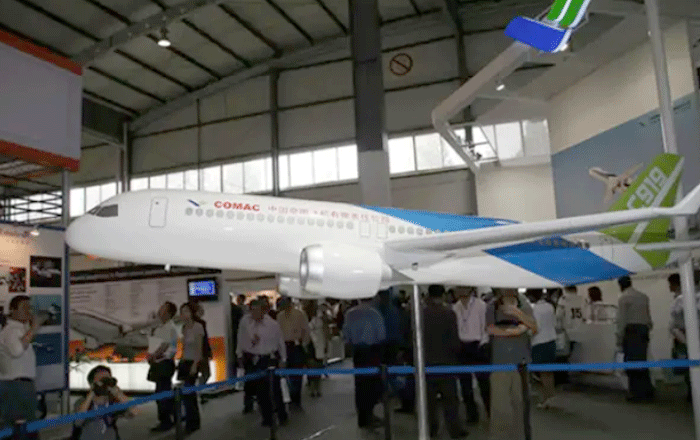

The C919 is the second domestically produced large passenger aircraft independently designed by China. The wings, horizontal tail and central wing box of this aircraft use composite material structural components.

Figure 16 C919

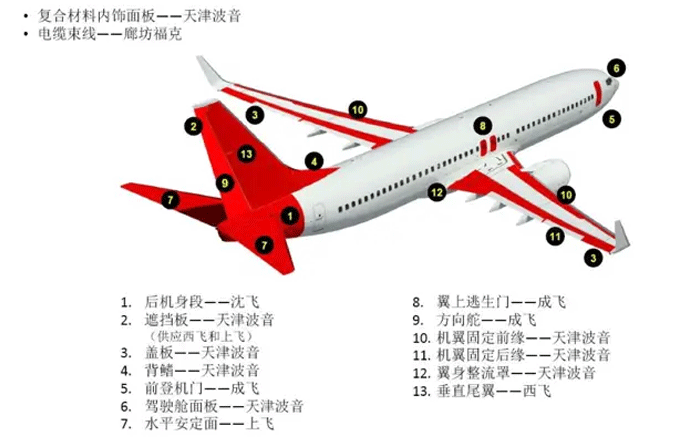

The following several pictures show the subcontracting situation of Boeing Company in China:

Figure 17 Subcontracting situation of Boeing 737 in China

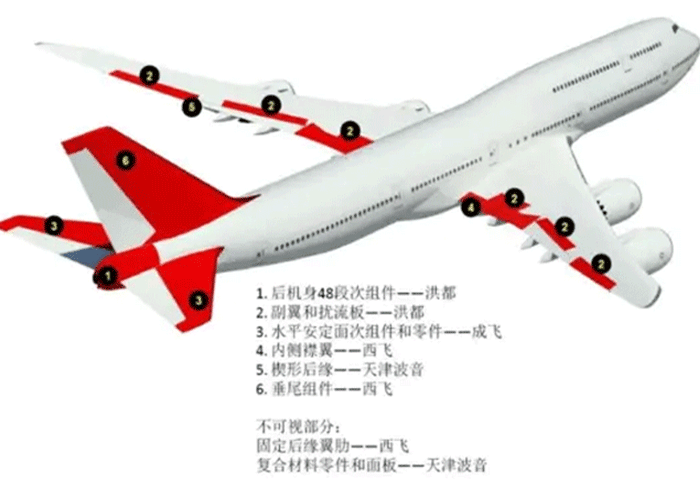

Figure 18 Subcontracting situation of Boeing 747 in China

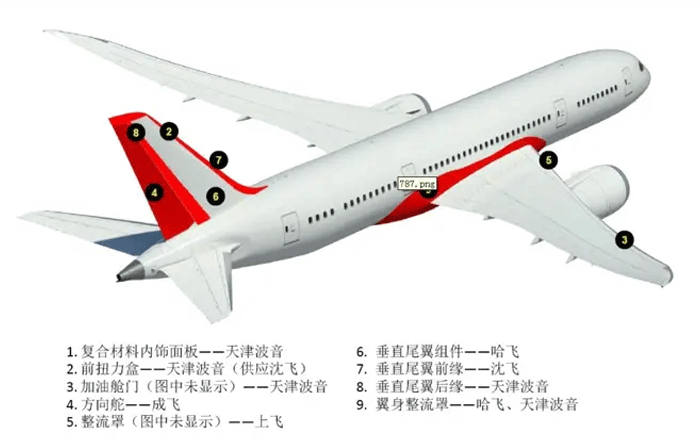

Figure 19 Subcontracting situation of Boeing 787 in China

Harbin Aircraft Industry Co., Ltd. submits and delivers composite aircraft components of the Airbus A350 and Airbus A320 series to members of the Airbus Group and/or suppliers designated by Airbus. Participate in the research, development, industrialization and mass production of current or future Airbus aircraft projects; Manufacture, sell, distribute and deliver composite aircraft components for third parties designated by Airbus. The company has signed seven work package contracts with Airbus and its Tier 1 suppliers, including the A320 elevator, rudder, flat tail beam and the A350 elevator, rudder, fuselage fairing, service cabin door, etc.

Figure 20 The scene of the first delivery ceremony of the A320 elevator of Harbin Aircraft Industry Corporation (Image from the Internet)

Figure 21 shows the scene of the first delivery ceremony of the A320 elevator of Harbin Aircraft Industry Corporation (Image from the Internet)

Xi 'an Aircraft Industry Co., Ltd. produces the entire wings of Airbus A320 aircraft and has become a Tier 1 supplier.

Figure 22 shows that the first pair of Airbus A320 wings produced by AVIC Xi 'an Aircraft Industry Co., Ltd. was assembled on the fuselage

In China, civil aircraft can adopt the method of international procurement to bridge the technological gap. For instance, this approach can be used for aircraft engines, some on-board equipment, components and materials. However, there are still many things in civil aircraft manufacturing that cannot be bought with money, such as the overall design capability of the aircraft, especially the integration capability, which relies on the accumulation of experience. For instance, telex operation is a core technology. Airbus has become relatively mature in this area. The Boeing 777 has also adopted telex operation technology, some of which are optical transmission technologies. Such technologies will not be sold to us by others; we can only rely on our own research and development.

In recent years, many domestic units have gradually carried out the research and development of light sport aircraft and achieved certain results. In September 2011, Shenyang Aircraft Corporation signed a cooperation agreement with Cessna Aircraft Corporation of the United States to develop and produce China's first Cessna 162 light sport aircraft with an aluminum alloy fuselage, which successfully made its maiden flight.

In 2012, Nanchang Hangkong University and Zhuhai Qiangen FRP Products Co., Ltd. jointly developed the" "Red-mouthed Ou" The sports aircraft is manufactured and formed with carbon fiber, glass fiber, epoxy resin, core materials, etc. in its structure. The main structures such as the fuselage and wings are made of carbon fiber composite materials, and some partitions are made of glass fiber composite materials. The local area adopts a sandwich structure, and is covered with a carbon fiber reinforced epoxy resin-based composite material surface panel on the outside. 90% of the aircraft structure is composite materials, making the aircraft light in weight and good in strength.

Figure 23 Black-headed Gull

Bodongfeng Aircraft Co., Ltd. independently developed the DF2 composite material two-seat light sport aircraft (as shown in Figure 24), and conducted a test flight in July 2008. The main load-bearing structures of the DF2 aircraft are all made of carbon fiber materials. The design starting point is relatively high, but it still needs further improvement.

Figure 24 Domestically produced DF2 all-composite material light sport aircraft

In June 2013, the electric two-seat light sport aircraft independently developed by Shenyang Aerospace University successfully made its maiden flight at Shenyang Faku Caihu Airport. This new type of clean energy aircraft uses lithium batteries as its power source and adopts a fully carbon fiber composite material structure for its fuselage. Compared with traditional oil-powered aircraft, it features low cost, energy conservation, environmental protection, safety and practicality. Liaoning Pacific Aviation Industry Co., Ltd. introduced the KIS-2 and KIS-4 designed in the United States. Both are two-seat and four-seat light aircraft made of composite materials. Their structures are mainly fiberglass reinforced plastic, and carbon fiber composite materials are used in some parts such as the wing frame and flat tail.

Figure 25 Blue Eagle AD200 aircraft

At present, composite sandwich structures are most widely used in light aircraft. Sandwich structures are typically made by bonding relatively thin panels as the surface layer and relatively thick, low-density materials as the core, such as honeycomb sandwich structures or foam sandwich structures.

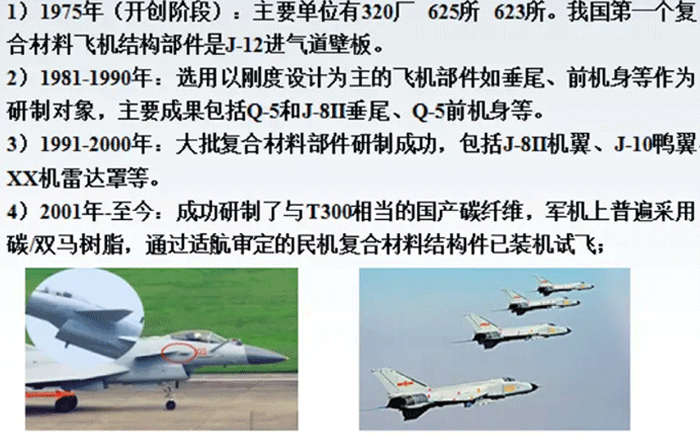

The usage of composite materials for domestic military aircraft is shown in the following figure:

Figure 26 shows the usage of composite materials in domestic military aircraft

2.2 Helicopter

1)Helicopter landing gear

The skid-mounted helicopter landing gear has a simple structure, light weight, stable performance and is not easy to be damaged. It mainly relies on the elastic deformation of the structure to absorb landing energy. Buoys can be installed for takeoff and landing on water surfaces or other special sites. This has significant advantages in civilian fields where aircraft speeds are slow, takeoff weights are light, sites are easy to guarantee, and logistics are relatively weak.

At present, metal matrix composites are more commonly used. Like all fiber-reinforced composites, metal matrix composites achieve a certain property by using different fibers, matrices and adjusting the fiber capacity, or through special structural design.

However, at present, the biggest drawback of metal matrix composites is that their fibers have low toughness, the production cost of the process is high, the process is very immature, it is difficult to achieve mass production, and they are expensive. Moreover, when designing with metal matrix composites, the connection method, load transfer path and vulnerable parts must be carefully considered to estimate the potential for weight savings, thus increasing the difficulty of the design. Metal matrix composites have poor shock absorption performance. When using this kind of material to make landing gear, complex shock absorption devices must be set up, which increases the weight and cost of the fuselage.

Carbon fiber/epoxy resin composite materials have comprehensive excellent properties and are more suitable for use as helicopter landing gear materials. Carbon fiber/epoxy resin composite materials can be designed according to the different requirements of the landing gear. The molding process, material grade and reinforcing materials can be reasonably selected based on the force conditions to achieve the purpose of cost saving and weight reduction.

Figure 27 Composite material helicopter landing gear (Image from the Internet)

2)Helicopter rotor blade

The rapid development of helicopter technology, especially rotor technology, is largely attributed to the application of composite materials. The advantages of composite materials have been fully exerted in the rotor blades, which provides the possibility for the improvement and optimization of the aerodynamic shape of the rotor blades and the optimization of the dynamic characteristics of the rotor. More importantly, the composite material significantly increases the service life of the rotor under alternating loads and enables "maintenance as needed". This not only enhances the safety of the helicopter, but also significantly reduces the manufacturing cost of the rotor blades, thereby bringing considerable economic benefits.

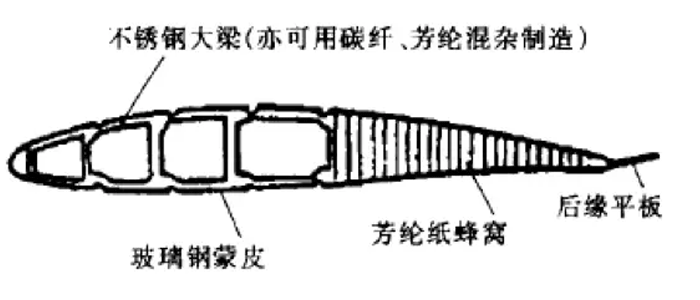

Figure 28 Plane view of the helicopter rotor

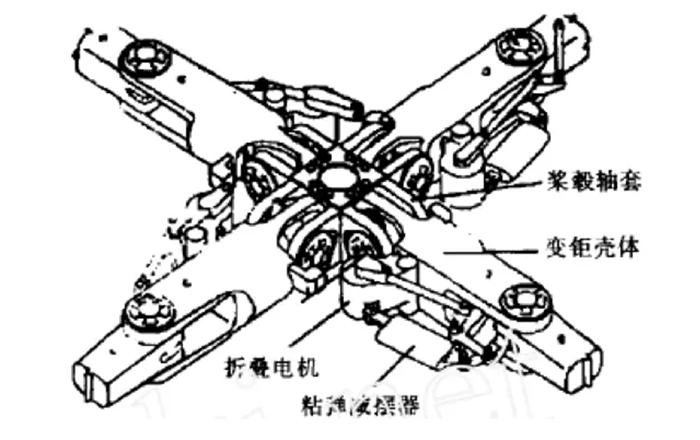

3)Helicopter propeller hub

Compared with the blades, the composite materialization of the hub is relatively difficult, but breakthrough progress has also been made. The star-shaped flexible rotor hub successfully developed by the French aerospace company in the late 1970s marked the first breakthrough in the application of composite materials in rotor hubs. Subsequently, various countries began to research and test composite material bearingless rotor hubs one after another, making it possible to fully composite the rotor structure. This is a revolution in the development of helicopter technology.

Figure 29 Hinged composite viscoelastic bearing hub of the Boeing 360 helicopter

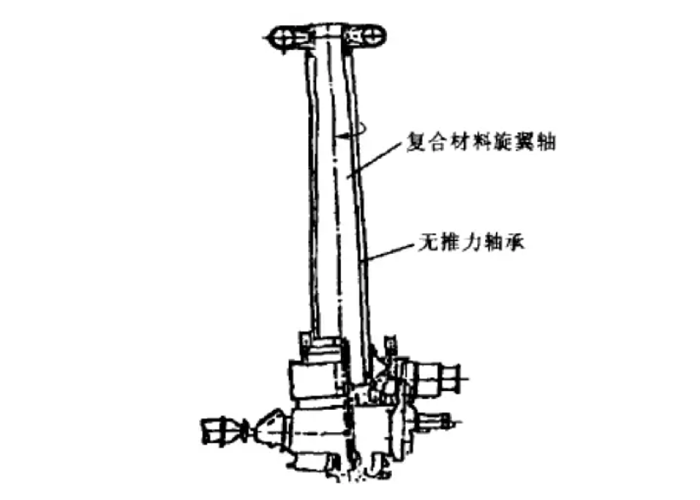

4)Helicopter transmission system

The application of composite materials in transmission systems has also been put on the agenda. Boeing, McDonnell Douglas, and Kaman Helicopter companies have all conducted extensive research work. Boeing has successfully adopted a rotor shaft and reducer housing with a mixture of graphite fiber and glass fiber wound on its 360 helicopter. The service life is unlimited, while the weight is reduced by 25%.

Figure 30 Composite rotor shaft of the Boeing 360 helicopter

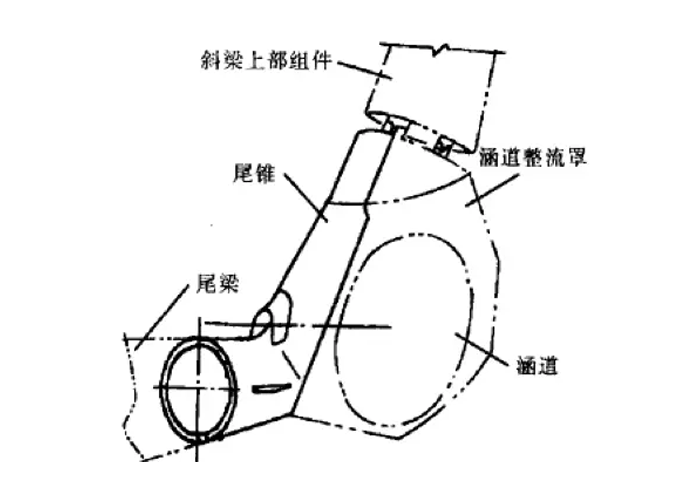

5)Helicopter fuselage

In recent years, the application of composite materials in fuselages has also made significant progress. The first fully composite material fuselage test flight was the S275 helicopter of Sikorsky Corporation. Subsequent test flights included the D2292 helicopter with a fully composite material fuselage of Bell Corporation and the Boeing 360 helicopter of Boeing Helicopter Corporation, etc. These helicopters have considerable benefits compared with the original standard aircraft in terms of fuselage weight, production cost, safety and maintainability.

Figure 31 Domestic straight -9 all-composite material culvert vertical tail

2.3 Special aircraft (Due to the large number and variety, only unmanned aerial vehicles are taken as an example here)

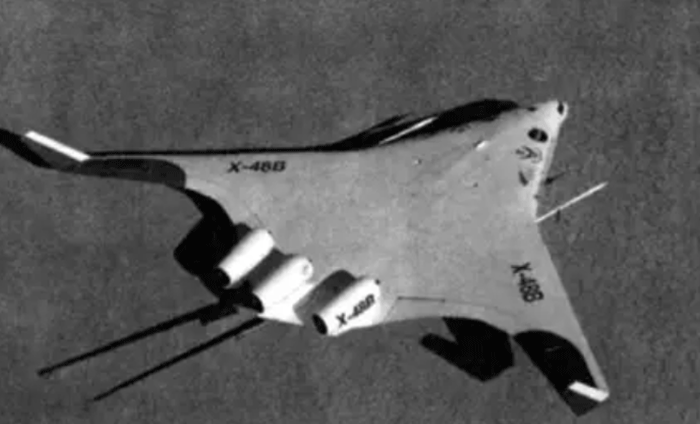

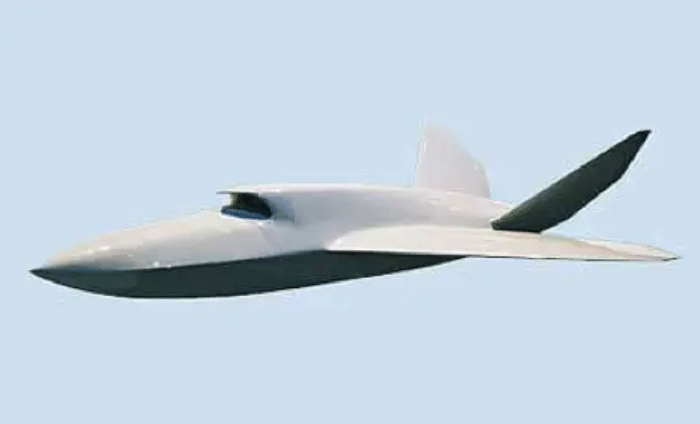

The composite material structures of unmanned aerial vehicles (UAVs) mainly include laminate structures and sandwich structures. Due to their strong designability, the number of UAV components and parts can be significantly reduced in the overall design of structural components. A typical application is the wing-body fusion structure, as shown in Figures 32-33.

Figure 32 American X-48B unmanned aerial vehicle

Figure 33 European "Barracuda" unmanned aerial vehicle (with a fuselage made of all-carbon fiber composite material)

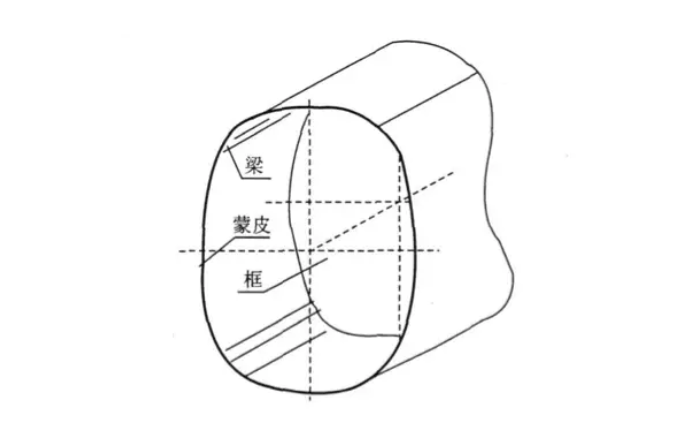

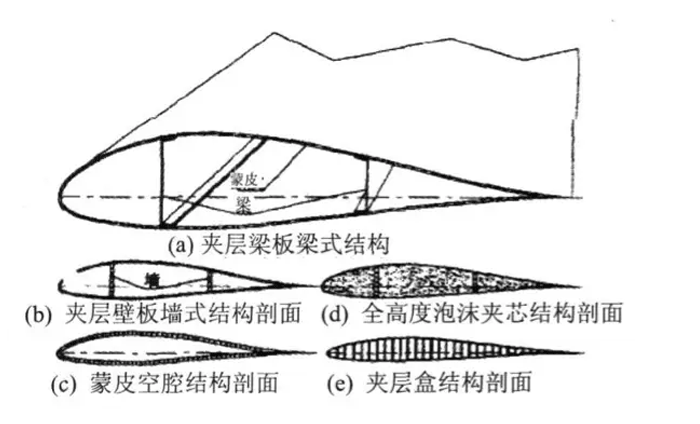

The structures used on unmanned aerial vehicles include sandwich structures and laminated plate structures. For example, the fuselage structure is composed of longitudinal beam flanges, skins and transverse frames, as shown in Figure 34. Among them, the skin is a honeycomb sandwich structure, and the flange of the beam is mostly a composite material laminate structure. The wing surfaces are mostly of sandwich panel beam structure, sandwich panel wall structure, full-height foam sandwich structure, skin cavity structure and sandwich box structure, etc., as shown in Figure 35:

Figure 34 Typical Structure of the unmanned aircraft fuselage

Figure 35 Typical Structure of unmanned wing surface

The reinforcing materials used in the composite structural components of unmanned aerial vehicles mainly include carbon fiber, glass fiber, etc., while the resin systems mainly consist of epoxy resin system and bismaleimide resin system. The former has better processability, while the latter has better temperature resistance.

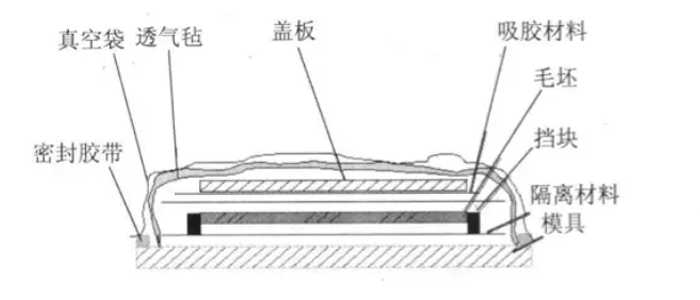

The manufacturing methods of composite material structural components for unmanned aerial vehicles mainly include autoclave forming, vacuum bag forming and compression molding.

Figure 36: Bagging of auxiliary materials for the autoclave forming process